Jan. 22, 26

What Are RC Drilling Tools?

Reverse Circulation (RC) drilling tools are specialized equipment designed specifically for the RC drilling method. These tools work together as a system to enable fast, efficient drilling while recovering high-quality, uncontaminated samples from great depths. Unlike conventional drilling tools, RC equipment is engineered to reverse the flow of cuttings—bringing samples up through the center of the drill pipe rather than the annulus.

Core Components of an RC Drilling System

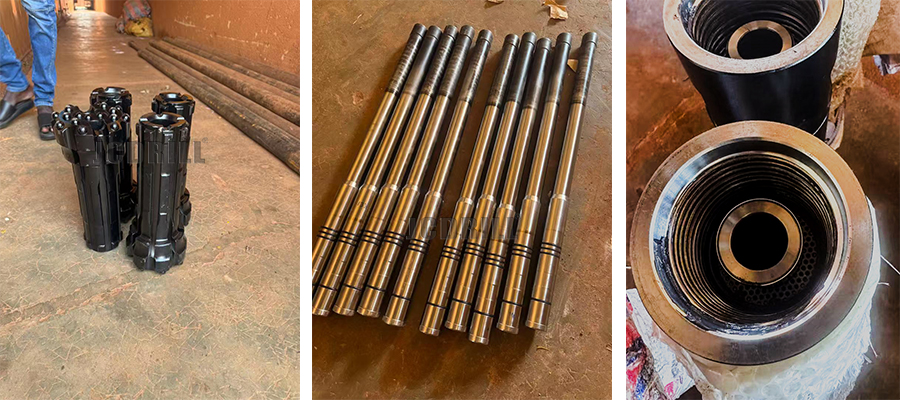

1. Dual-Wall Drill Pipe (The Heart of the System)

The dual-wall pipe is what makes RC drilling unique and effective. It consists of two concentric tubes:

· Outer Tube: Provides structural strength, transmits rotation to the bit, and serves as the conduit for compressed air going downhole.

· Inner Tube: A smaller, sealed tube that carries cuttings to the surface with minimal contamination.

· Quick-Connect Threads: Allow for rapid connections and disconnections, reducing tripping time.

· Materials: Typically made from high-strength, wear-resistant alloy steel with hardness treatments.

Key Benefit: The sealed inner tube prevents mixing of cuttings from different depths, ensuring sample integrity.

2. Down-The-Hole (DTH) Hammers

These are percussive tools that provide the cutting action in hard rock formations:

· Pneumatic Operation: Powered by compressed air (typically 350-500 psi)

· Valve Design: Controls the hammer cycle for maximum impact energy

· Carbide Buttons: Tungsten carbide inserts on the hammer face for rock fragmentation

· Size Range: From 4" to 9" diameter for different hole sizes

Types Available:

· Standard DTH Hammers: For general hard rock applications

· Deep Hole Hammers: Specialized for depths beyond 400 meters

· Low-Pressure Hammers: For operations with limited compressor capacity

3. RC Drill Bits

Specifically designed to work with the RC system:

· Face Designs: Button bits (most common), cross bits, or X bits

· Flushing Holes: Strategically placed to efficiently evacuate cuttings

· Gauge Protection: Extends bit life and maintains hole diameter

· Materials: High-grade steel bodies with tungsten carbide inserts

4. RC Sampling System

The complete setup for handling recovered samples:

· Blow Pipe: Transfers cuttings from drill pipe to cyclone

· Cyclone Separator: Uses centrifugal force to separate cuttings from air

· Sample Splitters: Divide continuous sample stream for analysis

· Collection Bags/Containers: For sample storage and transport

5. Specialized Subs and Adapters

Connection components that ensure system integrity:

· Swivel Subs: Allow rotation while maintaining air/fluid connections

· Drive Sub: Transmits rotation from rig to drill string

· Casing Adapters: For transitioning between hole sizes

Technical Specifications & Performance Data

Typical Operational Parameters

Parameter Range Notes

Drill Pipe OD 89-140 mm Common: 114 mm (4.5")

Hole Diameter 115-200 mm 130 mm most common

Operating Pressure 1.7-3.5 MPa 350-500 psi typical

Air Volume Required 17-35 m³/min 600-1200 CFM

Depth Capacity Up to 600 m Typically 100-350 m

Penetration Rate 20-50 m/hr Varies by rock hardness

Material Specifications

· Drill Pipe Steel: 4140/4142 alloy, quenched and tempered

· Hardness: 38-42 HRC for optimal wear resistance

· Thread Treatment: Induction hardening or special coatings

· DTH Components: Specialized tool steels with specific heat treatments

How RC Tools Work Together: The Complete Process

Step 1: Air Injection

· High-pressure air enters through the swivel

· Travels down the annulus between inner and outer tubes

· Powers the DTH hammer at the bottom

Step 2: Rock Fragmentation

· DTH hammer delivers rapid impacts to the drill bit

· Bit buttons crush and fracture the rock

· Cuttings are created at the rock face

Step 3: Sample Recovery

· Air pressure forces cuttings into the center of the bit

· Cuttings travel up the sealed inner tube

· Velocity maintains sample integrity and prevents settling

Step 4: Surface Processing

· Cuttings exit through blow pipe into cyclone

· Air is separated and vented

· Cuttings drop into sample splitter

· Representative samples are collected for analysis

Advantages of Modern RC Drilling Tools

For Exploration Managers

· Superior Sample Quality: Representative, depth-specific samples

· Rapid Drilling: Faster than diamond drilling for resource definition

· Cost Efficiency: Lower cost per meter than core drilling

For Drilling Contractors

· Durability: Extended service life reduces replacement costs

· Interchangeability: Standard threads across most manufacturers

· Ease of Maintenance: Modular design simplifies repairs

For Geologists

· Continuous Sampling: Virtually 100% sample recovery

· Minimal Contamination: Sealed system prevents mixing

· Large Sample Volume: Sufficient for comprehensive analysis

Application-Specific Tool Selection

1. Mineral Exploration

· Recommended: Standard DTH hammers with button bits

· Pipe Size: 114-140 mm OD for optimal sample volume

· Special Features: Wear-resistant materials for abrasive formations

2. Water Well Drilling

· Recommended: Larger diameter bits (6-9")

· Special Requirements: Corrosion-resistant materials

· Considerations: Ability to handle water inflows

3. Geotechnical Investigations

· Recommended: Smaller, more portable systems

· Focus: Sample quality over penetration rate

· Special Tools: Casing drivers for unconsolidated overburden

Maintenance & Best Practices

Daily Maintenance Checklist

1. Thread Inspection: Check for wear, galling, or damage

2. Hammer Lubrication: Proper oiling of DTH hammer

3. Air Filter Checks: Ensure clean air supply to tools

4. Sample System: Clear blockages in cyclone and pipes

Common Wear Parts & Replacement Intervals

Component Typical Life (meters) Signs of Wear

Drill Bit Buttons 500-1500 m Flattening, breakage

DTH Hammer Piston 2000-5000 m Reduced impact energy

Inner Tube 10,000-20,000 m Erosion, thickness reduction

Threads 500+ connections Difficult make-up, galling

Industry Standards & Certifications

Modern RC drilling tools are manufactured to meet international standards:

· API Specifications: For thread forms and material grades

· ISO Standards: Quality management and safety requirements

· Manufacturer Specifications: Often exceed industry standards

Quality Assurance Features

· Ultrasonic Testing: For detecting internal flaws

· Magnetic Particle Inspection: Surface crack detection

· Hardness Testing: Ensures proper heat treatment

· Dimensional Checks: Precision manufacturing verification

The Future of RC Drilling Tools

Emerging Technologies

1. Smart Tools: Sensors for real-time performance monitoring

2. Advanced Materials: Composites and ceramics for extended life

3. Automated Systems: Reduced manual handling and improved safety

4. Environmental Innovations: Noise and dust reduction technologies

Sustainability Focus

· Recyclable Materials: Increased use of recyclable alloys

· Energy Efficiency: Tools designed for lower air consumption

· Longer Lifespans: Reducing overall resource consumption

Selecting the Right RC Tools for Your Project

Key Considerations

1. Geological Conditions: Rock hardness, abrasiveness, fracturing

2. Project Depth Requirements: Shallow vs. deep hole tools

3. Sample Quality Needs: Degree of contamination tolerance

4. Available Support Equipment: Compressor capacity, rig capabilities

5. Budget Constraints: Initial investment vs. operating costs

Common Mistakes to Avoid

· Mismatched Components: Incompatible threads or sizes

· Insufficient Air Supply: Underpowered compressor for tool requirements

· Improper Maintenance: Leading to premature failure

· Wrong Tool Selection: For specific geological conditions

Conclusion

RC drilling tools represent a sophisticated system engineered for one primary purpose: to deliver high-quality geological samples quickly and economically. From the dual-wall pipe that defines the method to the specialized hammers and bits that make it effective, each component plays a critical role in the system's success.

RC drilling tools represent a sophisticated system engineered for one primary purpose: to deliver high-quality geological samples quickly and economically. From the dual-wall pipe that defines the method to the specialized hammers and bits that make it effective, each component plays a critical role in the system's success.

The continued evolution of these tools—with improvements in materials, design, and monitoring capabilities—ensures that RC drilling remains at the forefront of mineral exploration and geotechnical investigation worldwide.

For optimal results, always ensure: proper tool selection for your specific conditions, adequate supporting equipment, trained operators, and a proactive maintenance program. When these elements come together, RC drilling tools provide an unmatched combination of speed, sample quality, and cost-effectiveness.

Note: Specific tool recommendations should always be made in consultation with experienced drilling professionals who understand your unique project requirements.

Previous: Charitable Donation Warms Hearts, JCDRILL Demonstrates Responsibility

Next: CWD400T multi-function water well drilling rig completed and will soon be shipped