Drilling Diameter:115-152mm

Drilling depth:25m

Type: DTH Drilling, RC Grade Control Drilling

>> Introduction

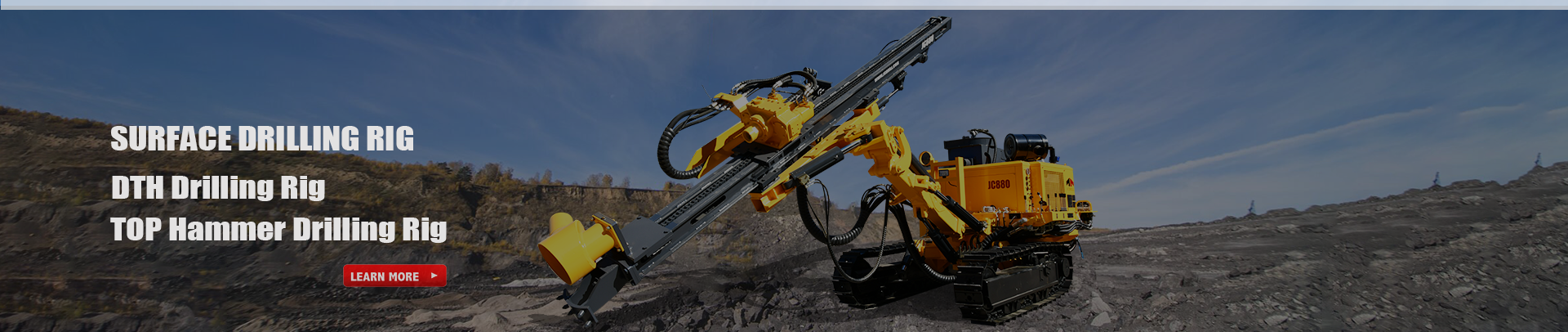

JC690R hydraulic drilling rig is designed for both Down-The-Hole (DTH) and Reverse Circulation (RC) drilling applications. Developed for high-efficiency mining, water well drilling, and geotechnical exploration, this rig combines powerful performance, automation, and environmental responsibility into a single machine.

Share

PRODUCT DESCRIPTION

The JC690R hydraulic drilling rig designed for both Down-The-Hole (DTH) and Reverse Circulation (RC) drilling applications. Developed for high-efficiency mining, water well drilling, and geotechnical exploration, this rig combines powerful performance, automation, and environmental responsibility into a single machine.

Built on a robust heavy-duty crawler undercarriage with wide tracks and 10° oscillation capability, JC690R ensures excellent stability and gradeability even on rough terrains. The machine is equipped with a Cummins QSL8.9-C360 turbocharged engine (359 horsepower), paired with a Sullair dual-stage rotary screw air compressor capable of 23 bar pressure and 19.5 m³/min air flow. These ensure high penetration rates in rock formations with hardness ranging from F=6 to F=20.

Key to its efficiency is the fully automatic rod handling system, enabling the operator to load and unload drill pipes with a single joystick. The rig also includes a full hydraulic dry-type dust collector, making it compliant with modern environmental standards and ensuring a clean and safe working environment.

With a maximum hole diameter of 152mm, drilling depth of 25 meters, and a torque output of up to 4300 Nm, the JC690R is an all-around performer in demanding drilling conditions.

1. Powerful Dual-System Drilling Capability (DTH + RC)

JC690R is engineered to switch easily between DTH and RC drilling modes, allowing operators to adapt to different geological formations and project requirements without changing rigs.

2. Industry-Leading Automation

The automatic pipe handling system allows fully automated rod storage, loading, and clamping via a single joystick. This reduces labor intensity, minimizes downtime, and increases operational safety.

3. Precision Control System

The operator-friendly control dashboard consolidates drilling parameters, system diagnostics, and alerts. Real-time display of rig angles and compressor pressure helps the operator optimize drilling accuracy and manage site operations efficiently.

4. High-Efficiency Powertrain

Equipped with a 359HP Cummins engine and a Sullair twin-stage air compressor, JC690R delivers reliable performance in even the hardest rock formations. Fuel injection and a dual-stage air filtration system increase fuel efficiency and extend engine life.

5. Superior Rotation and Feeding System

Featuring a USA Eaton hydraulic motor, the rotary head delivers up to 4300 Nm of torque and adjustable rotational speeds from 0–100 RPM. A stainless-steel reinforced feeding chain and dual cycloidal motors ensure smooth and jam-free operation.

6. Heavy-Duty Undercarriage and Maneuverability

The crawler-type undercarriage with 350mm wide tracks offers 10° oscillation, 20° gradeability, and 2–3 km/h travel speed, enabling swift transitions between drill sites and stability on uneven ground.

7. Hydraulic Dust Collection System

The rig includes a sliding-shield hydraulic dry dust collector to effectively trap drilling dust, improve air quality, and protect internal components — essential for long-term reliability and meeting environmental regulations.

8. Modular Design with Custom Options

The rig is compatible with optional RC cyclone separator and air box systems, making it versatile for mineral sampling, exploration, and precision drilling.

>> Specification

| Specification | Unit | JC690R | Brand | Cummins | |

| Drilling Specification | Model | QSL8.9-C360-30 | |||

| Rock Hardness | F=6-20 | Type | Water Cooling, 6 cylinder, EFI | ||

| Hole Diameter | mm | 115-152 | Rated Power | Kw/Rpm | 264/2100 |

| Hole Depth(DTH& RC) | m | 25 | Fuel tank capacity | L | 600 |

| Drill Pipe Changer | Rotation | ||||

| Drilling Rod Diameter | mm | 76,89,102 | Rotation rate | rpm | 0-100 |

| Drill rod length | m | 4 | Max.Rotation torque | Nm | 3400/4300 |

| Pipe Capacity | Piece | 5+1 | Feeding method | Motor+Chain | |

| Hammer size | 4"-5" | Feeding force | Kn | 12 | |

| Air Compressor | Lifting Force | Kn | 20 | ||

| Brand | Sullair | Undercarriage | |||

| Type | Two Stage, rotary screw | Track width | mm | 350 | |

| Pressure | Bar | 23 | Ground Clearance | mm | ≥400 |

| Max. FAD. | M³/min | 19.5 | Oscillation | ° | 10 |

| Feed System | Walking Speed | km/h | 2-3 | ||

| Feed Stroke | mm | 5550 | Grade Ability | ° | 20 |

| Feed Extension | mm | 1100 | Dust Collector | ||

| Engine | Collecting type | Full hydraulic | |||

>> Application

Open-Pit and Underground Mining Projects

Ideal for high-efficiency blast hole drilling, mineral exploration, and sampling in both surface and underground settings.

Geological Survey and Exploration Drilling

Accurate and reliable for reverse circulation drilling and core sampling with optional RC modules.

Water Well and Geothermal Drilling

Efficiently drills medium-depth wells in various soil and rock layers, ideal for rural or remote water access projects.

Civil and Infrastructure Projects

Applicable in foundation drilling, anchor bolt hole drilling, and slope stabilization in highways, bridges, tunnels, and dams.

Environmental and Hydrological Investigations

Delivers precision and dust control for scientific sampling and monitoring of groundwater and soil.

Accuracy Matters

Delivers uncontaminated RC samples for reliable ore grade analysis

Ensures precise boundary mapping between waste rock and high-value ore

Cost-Effective Decision Making

Reduces dilution risks by up to 30% vs. traditional methods

Provides critical data to determine mining feasibility and profitability

Engineered for Mine Geologists

Fast relocation between drill sites

Minimal sample loss for trustworthy assay results

>> Shipping

TAGS:

KG520 Geotechnical Down The Hole Drilling Rig for Rock Blasting

Kg610 Powerful Down The Hole Rock Blast Earth Drilling Machine

JC880 hydraulic DTH Drilling Machine Blasting Hole Rock Drilling Rig For Mining

JC900 Hydraulic Crawler DTH Rock Blasting Rotary Drilling Rig

JCM400 Multifunctional DTH Rock Drilling Rig – Fully Hydraulic Top-Drive Rotary Crawler Drill

JC103A DTH Rock Integrated Drilling Rig – High-Efficiency Hydraulic Drill for Mining & Quarrying

JC617 Compact Crawler DTH Drill Rig – 30m Depth, 90-100mm Holes, 2400Nm Torque for Confined Spaces

JC618GF Photovoltaic Pile Drilling Rig – 90-400mm Diameter, 10m Depth

JC843 High-Efficiency DTH Drill Rig Rapid-Cycle Drilling Solution for Time-Sensitive Projects

JC712 Export Extended Reach Drilling System DTH Drill Rig for Deep Bore Applications

JCM200 Multifunctional DTH Rock Drilling Rig – Fully Hydraulic Top-Drive Rotary Crawler Drill